The production process of non-glue fiber is roughly as follows:

Bale opener→Pre-opener→Mixer→Fine opener→fiber feeder→Carding machine→Cross lapper→Thermal bonding oven→Ironing machine→Winding machine

Specific customization is required according to customer needs.

This production line is mainly used to produce non-glue fiber. Non-glue fiber is widely used, such as clothing, bedding, furniture, etc. The oven in this production line adopts electric heating and gas heating, adopts upper blowing and lower suction, hot air penetration, high hot air efficiency, high output, and good final product effect.

1. Bale opener: Opens various bales of fibers, weighs them in proportion on an electronic scale, and evenly spreads them on a fiber blending curtain. Various fibers are placed on a horizontal conveyor curtain, fed by a fiber pressing roller and a pair of rollers, and then loosened by a high-speed beater and sent to the next process by a fiber conveying fan.

2. Opening machine: The company developed a special alloy card cloth opening machine, which is transported by a fan. The feeding is a wooden curtain or a leather curtain. The feeding is controlled by the photoelectric control on the fiber feeder. Two groove rollers are used for feeding and two springs are used for pressure. The opening rollers are dynamically and statically balanced, with a conveying air duct, and are fully enclosed to reduce the number of machine cleaning times.

3. Vibrating feeder: further loosens and mixes the opened fibers, and processes them into uniform matting fiber for the next process. Volumetric quantitative feeding, photoelectric control, easy adjustment, accurate and uniform fiber feeding.

4. Carding machine: This machine has single cylinder, double doffer, four random, roller stripping. All rollers of this machine are tempered and qualitatively treated before precision machining. The wallboard is made of cast iron, the card clothing is made of domestic high-quality card clothing, and it is equipped with a suction device to reduce the number of machine cleaning times, and it also has a walking platform. It has the advantages of strong carding ability and high output.

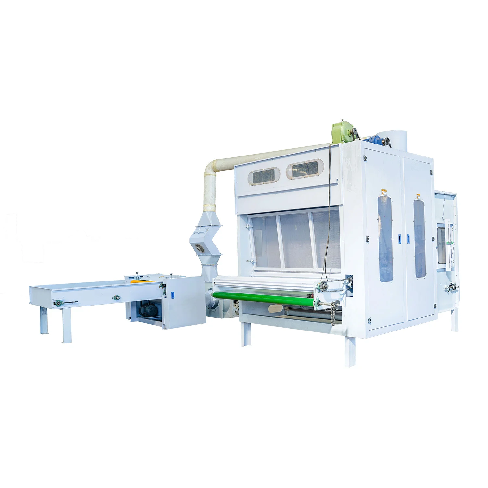

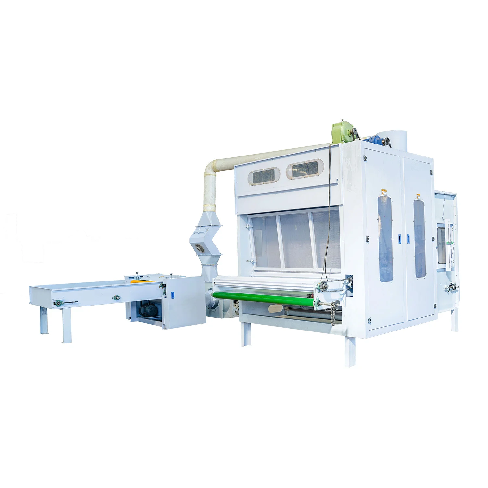

5. Cross lapper: The frame is made of 6mm steel plate, and a compensating motor is added between the net laying curtains to reduce the draft of the fiber net. The reciprocating reversing is controlled by frequency conversion, with small impact force, automatic buffering and balanced reversing, and equipped with multi-speed control. The bottom curtain can be adjusted to rise and fall, so that the fiber net can be evenly laid on the bottom curtain according to the required unit weight for use in the next process. The oblique curtain, flat curtain and cart flat curtain are made of high-grade leather curtains, and the bottom curtain and ring curtain are made of wooden curtains.

6. Oven: Heats the product evenly through high temperature

7. Cutting and winding machine: This machine is made of steel plate structure. The frame is welded from a whole piece of steel plate, integrating transmission and operating system. Three hard cutting knives are used for cutting in the longitudinal direction, and one flying knife is controlled by an electronic meter in the transverse direction. The structure is simple, beautiful and generous.